1. INTRODUCTION

Rice bran is produced as by-product during rice milling. After de-husking, brown rice is obtained that are polished during rice milling to get white rice. The outer brown layer of unpolished rice is known as bran and it contains around 18%~20% of oil.The parboiled rice bran contains higher amount of oil(around 22%~24%). This is extracted by using hexane as solvent. The global market for rice bran oil has grown at a steady rate of around 3% annually in last several years. Rice bran oil has a balanced fatty acid composition, one of the nearest to that prescribed by different health organizations. The added benefits are the presence of a number of nutritionally rich constituents like oryzanol, tocopherol, tocotrienol,phytosterols, steryl esters, squalene etc. that make this oil very attractive for human consumption. However,there are many processing challenges one has to overcome to produce a good quality edible rice bran oil. These challenges make this oil most difficult to refine. In this section, the problems faced by the industry and their potential solutions in India are discussed in brief. India is the largest producer of rice bran oil followed by China and Japan. Other countries like Indonesia, Bangladesh, Vietnam also started producing edible grade rice bran oil and quite significant process developments were observed in the last decade.

2. EXTRACTION OF CRUDE OIL FROM RICE BRAN

Extraction of rice bran oil is more or less a matured technology now. As the bran contains around 20% of oil, it is preferably subjected to solvent extraction process and throughout the world hexane is used as the extracting solvent. In most of the cases, bran is pelletized for better extraction efficiency and solvent is percolated through these pellets and oil containing miscella is produced. This is then processed through desolventizer toaster after miscella filtration. Different types of extractors like Rotocel Extractor, Loop Extractors and Towline Extractors are used. The final step is hexane recovery. The major challenge in solvent extraction unit is the energy efficiency, extractability, minimum hexane loss and removal of fines through proper filtration of miscella[1]. Integrated heat recovery is placed in many solvent extractor plants. In recent years the use of nitrogen is also reported in desolventizer/toaster instead of steam to reduce energy requirement further. Improved filtration equipments are also included in the extractor to reduce fines in the oil. This has immense benefit in getting good quality oil. The modern design of desolventizer-toaster and the hexane distillation unit ensures hexane loss of as low as 0.1%. As hexane is already listed by USEPA as hazardous chemicals, in near future alternatives of n-hexane have to be tested for economic and technical feasibilities.Supercritical carbon dioxide is being projected as one of the feasible alternatives. Researchers has tested other solvents like alcohols, limonene, isohexane etc. However, all commercial units in the whole world still use hexane as solvent for extraction of rice bran oil.

3. PROCESSING PROBLEMS FACED BY INDUSTRIES AND THEIR POSSIBLE SOLUTIONS

Rice bran oil is not obtained from seeds like most of the other oils. Therefore, it has some inherent quality parameters which make it very difficult to refine for human consumption[2]. However, the fatty acid composition of the oil and presence of many nutritionally rich minor constituents suggest that if properly refined, it would be one of the most preferred cooking oils. The most important disadvantage of rice bran oil is presence of higher amount of free fatty acids (FFA). The bran contains typical lipase enzymes that cleave the triglyceride molecules liberating more and more FFA with the time. The amount of FFA is increased to that extent,the refining by conventional alkali neutralization methods becomes economically not viable. The physical refining should be primary alternative.Crude rice bran oil is also having more amounts of gums and waxes compared to other common vegetable oils. The gums are nothing other than phospholipids.Efficient degumming is one crucial step in refining.Similarly, waxes are non-edible and create problems during refining. Hence, waxes are to be removed.Crude rice bran oil is dark in colour and not aesthetically acceptable to the consumers. Special attention has to be given for removal of colouring pigments. Consumers prefer odour less oil for cooking to have the characteristic flavour of the food. Thus,deodorization is another important step in refining.As the Rice bran oil is having lots of nutritionally rich minor constituents, proper technologies have to be adopted to retain all these components as much as possible to increase the food value.

4. DEACIDIFICATION – CHEMICAL REFINING VIS-A-VIS PHYSICAL REFINING

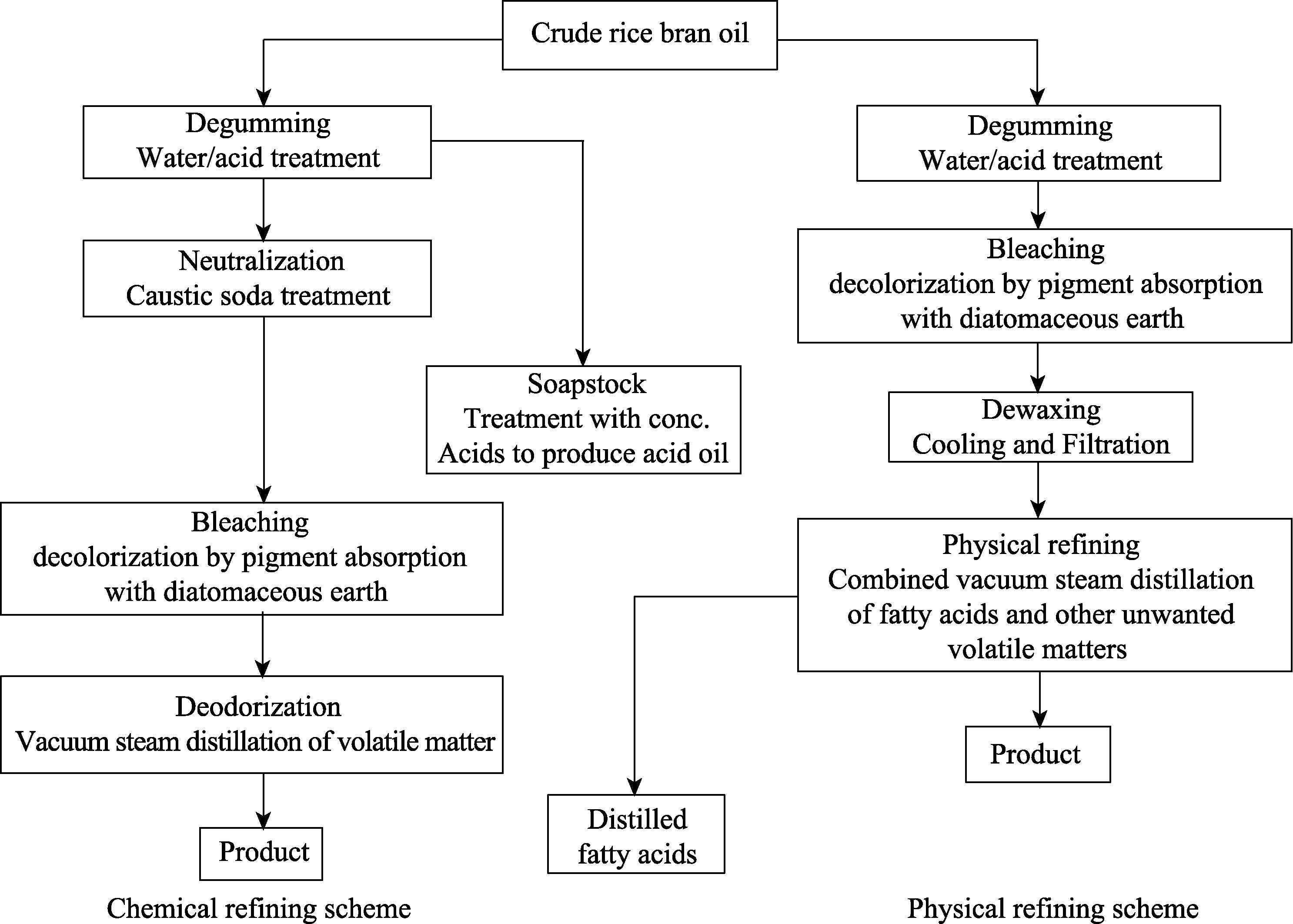

In Figure 1, various stages of physical and chemical processes are demonstrated in a typical production technology. In chemical refining alkali is added to the crude oil in little excess to the stoichiometric requirement to neutralize the FFA present in the crude oil. This neutralization reaction produces soaps (sodium salt of fatty acids) if NaOH is used for neutralization. The soap is not edible and has to be washed out using repeated water washing.Soap is surfactant and produces strong emulsion in presence of oil and water. This always increase oil loss. Since FFA of crude rice bran oil is more, more alkali has to be added for neutralization that results in formation of more soapstock and hence increased oil loss. This makes the process uneconomical. The presence of higher amount of other emulsifiers like monoglyceride, diglycerides, phospholipids and glycolipids make the process more complicated and adds to the processing loss of oil. On the other hand,most of the phenolic antioxidants and micronutrients like oryzanol, tocols, phytosterols present in the rice bran oil will be stripped off from the oil and will go with the soapstock immensely reducing nutritive value of the oil. The soapstock needs to be treated before it is disposed off. Generally this is acidulated to produce acid oil and the wash water thus generated contain very high amount of total dissolved solids(TDS) creating environment hazards.

Fig.1 Processes of chemical and physical refining

In physical refining process, FFA are removed by steam stripping using open steam at higher temperature (220~250 ℃) along with the removal of odoriferous compounds. Very high vacuum has to be maintained during this process. The prerequisite of physical refining is the phosphorous content of the oil going to de-acidification unit should be less than 5 mg/L. If efficient degumming and dewaxing processes are practiced as pre-treatment before physical refining very good quality rice bran oil can be obtained. This process is environment-friendly and most of the micronutrients can be retained in the refined oil[3].

It is quite evident from this discussion that,physical refining should be the preferred method for refining of rice bran oil. Most of the industries in India have shifted to physical refining and the industries in China, Japan and other countries like Bangladesh, Indonesia, and Vietnam are gradually shifting towards physical refining.

5. RAW MATERIAL QUALITY AND PROPER MANAGEMENT

The FFA content is the most crucial factor for economical production of good quality rice bran oil.The oil has to be extracted from the bran as early as possible after rice milling. This will prevent increase of FFA and also the amount of partial glycerides like MG and DG. If the FFA content of the oil is very low (1%~2%), alkali refining can be done as the soap stock formation will be limited.However, significant amount of the micronutrients will be lost during chemical refining. One approach is to stabilize the bran immediately after milling to restrict the increase of FFA contents. However, the stabilization may cause colour fixation of oil due to heating. The ‘p’ content, the bleachability, the peroxide value, and p-anisidine value have to be determined before initiating the refining process.These parameters will throw light on quality of the crude oil and accordingly refining strategies can be adopted. Most of the industries segregate the crude oil samples based on the quality parameters and follow suitable processes for refining. The oil samples having FFA content more than 3% and oils having more of the other impurities will definitely go for physical refining. In a well-planned industry consortium, the solvent extraction plant is surrounded by many rice mills. The solvent extraction plant employs many vehicles to collect the fresh bran from all the mills immediately after de-braning and these are fed to the extraction plant to keep the quality parameters within specified limits for economical production of nutritionally enriched refined rice bran oil.

6. PROBLEMS IN DEGUMMING OF RICE BRAN OIL AND POTENTIAL SOLUTIONS

The first and most crucial pretreatment step is degumming of raw oil in which phospholipids,metal ions and other impurities are removed. These components if not removed efficiently, eventually may create problems in subsequent refining steps. The major constituents to be removed are phospholipids(primarily Phosphatidyl Ethanolamine (PE),Phosphatidyl Choline (PC), Phosphatidyl Inositol(PI) and Phosphatidic Acid (PA) which are in either hydratable or non-hydratable forms. These are all good emulsifiers and will result in more loss during further refining steps. Moreover, they will darken the oil irreversibly when heated to higher temperatures during subsequent refining steps.Hydratable phospholipids can be removed easily by water degumming using 2%~3% water at around 80 ℃followed by centrifugation. However, rice bran oil contains significant amount of non-hydratable phospholipids and therefore, require additional treatment. Phosphatides bound with monovalent metal (such as sodium or potassium) are generally hydratable. On the other hand, phosphatides bound to bivalent metal ions (such as calcium or potassium)are non-hydratable. It is also observed that at pH 6 and 7 the possibility of complex formation of Ca+2,Mg+2 with PA and PE is very high and the binding strength of bivalent ions is 1000 times greater than monovalent ions. The addition of sufficiently strong acid liberates metals from these two phospholipids.Subsequently, bivalent metal ions bind with added acid and are removed with water. Addition of phosphoric/citric acids for converting the nonhydratable gums to hydratable gums is a very common practice in rice bran oil industry and this process is called acid degumming. This leads to lower residual phosphorous, metal content compared to water degumming. However, acid degumming could not bring down the phosphorous content of the oil to < 5 mg/L even after bleaching and dewaxing for most of the rice bran oils. Moreover,due to the presence of acids, the gums produced cannot be utilized for lecithin recovery. Inefficient degumming has huge impact on bleaching. It causes requirement of higher amounts of bleaching earth causing more oil loss. It creates foaming in the bleached and most of the adsorption sites are used for adsorption of gums. Super degumming suggested by few researchers, results in lower residual phosphorous than standard acid degumming;however, these levels are quite dependent on raw oil quality. Membrane degumming is another process where it can remove all undesirable components such as gums, mucilage, polar materials, colouring pigments, metal contaminants etc. in a single step from raw rice bran oil. Due to non-availability of economically viable solvent-resistant membranes,less throughput of membranes and fouling of membranes presently no commercial plants are using membrane degumming for rice bran oil.

Enzymatic degumming of rice bran oil is the well-established process where phospholipids are converted to lysophospholipids and because of its hydrophilic nature, can be separated easily from the bulk oil. Initially this process was developed for soybean oil. For the development of industrial enzymatic degumming process of RBO commercially available phospholipase A1 was employed. This process is currently being practiced in India in most of the rice bran oil processing plants for the production of good quality physically refined rice bran oil keeping majority of the nutraceuticals intact in the oil. Enzymatically degummed, bleached and dewaxed rice bran oil exhibited phosphorous content to the requisite amount (< 5 mg/L) and also oil losses are minimized employing this process.China and Japan have also started using this technology[4-7].

7. BLEACHING OF RICE BRAN OIL –PROBLEMS ENCOUNTERED AND POSSIBLE SOLUTIONS

Rice bran oil is darker compared to most of the other major edible oils due to the presence of colouring components like carotenoids, xanthophyll,pheophytins, chlorophyll. The degummed oil also contains residual soaps (if alkali is added for neutralization) phosphatides, high molecular weight oxidative products and trace metals. Bleaching is practised after neutralization if chemical refining is done or after degumming in case of physical refining is the preferred route. It is observed that the red pigments are more in rice bran oil compared to other oils. The red pigments have significant contribution in colour reading. Special strategies are to be adopted to reduce the red pigments. Chemical refining always yields less coloured oil as alkali decolorizes the dark pigments. However, as alkali refining has very limited scope in rice bran oil refining, commercially viable processes are to be designed to reduce the colour to a significant extent.Spent bleaching earth contains 25%~30% oil and hence results in oil loss in refining. It has to be planned in such a way that maximum amount of colour reduction is achieved with minimum amount of adsorbents. Generally activated bleaching earth like montmorillonite, bentonite, and hormites are used as adsorbent. For reduction of red pigments activated carbon is also used. Some manufacturers have produced bleaching earth specifically designed to reduce the red colour of rice bran oil. This in combinations with activated carbon reduces the colour of rice bran oil significantly.

Efficient degumming is very essential for the success of bleaching operation. If phosphatides are not efficiently removed in degumming, a portion of the bleaching earth is used to adsorb the phospholipids and in case of chemical refining these is also used to adsorb residual soap. Inefficient degumming also causes foaming in the bleacher.This results in reducing of vacuum to control the foam. This reduces the bleaching efficiency. In case of rice bran oil, it is advised to reduce the phosphorous content to the lowest possible limit in degumming step itself.

A very well maintained bleacher is another most important factor. The temperature has to be maintained around 105–110 ℃with vacuum around 700 mm of Hg. The batch bleachers have become obsolete and most of the industries have gone for continuous bleaching with pressure leaf filters for filtering the hot bleached oil. To improve the colour of the bleached oil further, counter current bleaching processes are introduced where 40% less bleaching earth consumption is reported. Depending on the demand of the market, two stage bleaching is also practised by industry. Two stages bleaching uses reduced quantity of adsorbents and results in less oil loss and lesser operating cost. Some rice bran oil samples show greenish/bluish tinge. This may be due to the inferior quality of bran or presence of higher amount of chlorophyll pigments.Addition of little amount of citric/phosphoric acid also help in getting better colour of oil. Another important factor is the addition of bleaching agent and impeller design (in case of batch bleacher). A fully automatic smooth dosing system with proportional flow of the oil will result in good quality and light coloured bleached rice bran oil[4-7].

8. DEWAXING–PROBLEMS AND REMEDIES

Another disadvantage of rice bran oil is that it contains waxes which are not edible, creates haziness of the oil and are to be removed efficiently.Waxes are esters of high molecular weight fatty alcohols and fatty acids. These are extracted using solvent along with the oil from the bran. It is Waxes are to be removed from the rice bran oil preferably at the level of <10 mg/L to pass a cold test which is necessary in cold countries to get the consumer acceptance. Since the dewaxing process involves the steps such as formation, maturation of wax crystals and slower filtration, this process is being considered as rate determining step of the whole rice bran oil refining process. The more nuclei formation and larger size crystal growth are the symbols of dewaxing success. The systematic and slower cooling plays significant role in dewaxing.Another crucial factor is presence of trisaturatebased triglyceride molecular species or higher amount of saturated fatty acids. This can be taken care by performing dewaxing firstly at a comparatively higher temperature followed by low temperature winterization to produce transparent oil that can easily pass cold test. Therefore, selection of process parameters is important in the dewaxing process.

Initially hot oil at around 75-80 °C is taken into the crystallizer and then it is cooled to 35–38 ℃using water from cooling tower within 2~3 hrs. This oil is further cooled to crystallization temperature by chilled water at a rate of 2~3 ℃/h. It is noteworthy that the water temperature should be maintained at 4~5°C lower than the oil temperature.The oil should be kept at crystallization temperature and enough time is to be given to get the crystals under mild stirring. After enough crystal formation the oil is to be filtered. This whole process takes about 10~12 hrs. Slow agitation using specially designed agitator is needed for preferred formation of crystals. Even though, the crystallization temperature plays significant role in efficient dewaxing, the other issues like characteristics of paddy, its processing history and geographical location etc. are also having considerable influence.For example, it is noticed that the operation of oils obtained from parboiled rice bran is much easier compared to raw bran. The temperature of surroundings and moisture content of oil also play significant role. The oil should be dried properly before performing the dewaxing as the moist oil may alter crystal formation and filtration rate.Efficient degumming is prerequisite for successful dewaxing of rice bran oil as otherwise, it will lead to formation of improper wax crystals. Therefore,the phosphorous content should be not more than 10~20 mg/L. Slow agitation maintains uniform composition, minimizes heat and mass transfer gradient and this provide slow moment of crystals for enhanced nucleation and growth. Under controlled parameters and in very well designed crystallizers having 12~15 tons capacity the preferred crystals can grow within 8~12 h. However,the individual industries have their own fine-tuned strategies to adjust the process parameters based on the quality of oil[4-7].

9. DEODORIZATION/DEACIDIFICATION OF RICE BRAN OIL - RELATED PROBLEMS AND SOLUTIONS

Deodorization is the final step in rice bran oil refining. In case of physical refining this unit operation is also used for simultaneous removal of free fatty acids and hence, known as simultaneous Deodorization/Deacidification step. In this step,other volatile compounds including oxidative breakdown products like aldehydes and ketones,pesticide residues, some colouring materials etc.also come out with FFA and odoriferous compounds.This can be achieved by passing open steam through the bulk of the oil at temperature higher than 200 °C and under very high vacuum for most of the vegetable oils. In case of rice bran oil where FFA content is very high and the oil itself, is dark in colour, utmost care has to be taken in choosing the temperature and time of exposure of the oil at that particular temperature. The high vacuum has to be maintained very strictly. Air leaks through flanges,pump seals and also through barometric legs are to be avoided. Steam pressure and cooling water temperature are also to be maintained very carefully.

Since, the FFA has to be removed efficiently,the deodorization/deacidification is done at a higher temperature in case of rice bran oil. Though it is suggested that temperature should be around 250 ℃at 1~3 mm/Hg[8], some reports showed that the temperature may go little higher[9]. The time of exposure should be less at that temperature as at high temperature there exists the possibility of trans-fat formation. This is another important quality parameter that has to be monitored very strictly. Chen et al[10]developed a low temperature deodorization process for rice bran oil where the oil was treated under high vacuum at 160~170°C for 5 min and 180~190 ℃ for 1~1.5 h and then ultrafiltered. They have suggested a refining protocol for rice bran oil having a water circulation step, a deodorization cum deacidification step and a decolouration step[10]. Thin-film deacidification and deodorization was also proposed by some researchers[11]. Keeping all these details in mind,reliable plant and machinery suppliers worldwide have slightly redesigned their deodorizer/deacidifier so that it can cater the need of production of nutritionally rich and low-trans rice bran oil.These systems are properly designed to take care of wide range of FFA present in rice bran oil. The ‘p’content of the oil has to be less than 5 mg/L before it is fed to the deodorizer/deacidifier. Otherwise, the oil will be darkened irreversibly. Therefore, an efficient pretreatment process, specifically proper degumming technique has to be in place. If all these precautions are taken, the problem of colour reversion will also be minimized. In some industries small dosing of citric acid are done to get aesthetically better finished oil.

10. WINTERIZATION OF RICE BRAN OIL

At lower temperature, rice bran oil develops haziness due to the presence of waxes and triglycerides having more amounts of saturated fatty acids. This physical property prevents RBO to pass cold test at 5 ℃ and hence, requires further processing called Winterization. The dewaxed and winterized rice bran oil has worldwide consumer acceptance including the cold areas. Rice bran oil dewaxing at lower temperatures (approx. 8~10 ℃)is proved to be difficult due to the presence of considerable amount of saturated fatty acids (approx.20%). In order to get the clear oil the winterization must be performed at lower temperatures compared to dewaxing temperatures. In some studies highest separation efficiency (89.1%) was obtained using the centrifugation operation and under cooling rate of 2 ℃ per hr (from 30~20 ℃) and 0.5 ℃ per hr(from 20~10 ℃) to get the lowest melting rice bran oil having highest percentage of oleic/linoleic acids. This indicates near total removal of saturated fatty acid triglycerides from rice bran oil. In another investigation, the rice bran oil was introduced into a winterization tank and then preheated to 50 ℃which was followed by cooling at 1.5 ℃/hr to 5 ℃under slow stirring for 24~40 hrs. The quality of rice bran oil obtained after filtration of contents passed the cold test and had wide consumer acceptance. In hot countries, however, winterization is treated as an optional process.

It is quite evident that from the above discussion that, though rice bran oil has many inherent problems for refining, commercially viable technologies are available to overcome these problems and very good quality rice bran oil with most of its nutraceuticals kept intact in it can be produced adopting appropriate technologies and with the inputs of trained manpower. Most of the equipment used in the present rice bran oil industry are made up of mild steel and replacing these with proper quality of stainless steel equipment, will definitely improve the quality and shelf life of the oil.

REFERENCE

See in its Chinese version P35.