绿豆是我国传统常食豆类之一,其淀粉、蛋白质、脂肪含量配比优于一般谷类[1],含有丰富的膳食纤维、黄酮类化合物(主要成分为牡荆素和异牡荆素[2])、功能性低聚糖、生物碱以及固醇[3]等功能性物质,具有清热解毒[4]、抗氧化[5]、提高免疫力[6]、降低退行性疾病[7]、预防肿瘤[8]等作用,是一种食药兼备的优良谷物。已有显著的研究表明,绿豆在发芽过程中营养成分发生改变,蛋白质、淀粉大分子物质分解为易于人体吸收的氨基酸、多糖等小分子物质,合成新的酶,同时释放更多的矿物质及新合成维生素 C[9];除此之外,膳食纤维,功能性低聚糖等功能性物质含量有显著的增加[10],酚类物质及生物碱含量也有提升[11]。

目前国内大多数研究集中在绿豆酸奶的研制工艺上。李海涛等[12]以绿豆浆、超微绿豆粉和鲜牛乳为原料,研制了凝固型绿豆酸奶,同时发现植物乳杆菌可用于绿豆酸奶的发酵。申灵[13]等研究了含谷粒发酵绿豆酸奶的工艺条件,李海燕[14]、张如意[15]也都对凝固型绿豆酸奶的研制进行了探究。因此,本研究选择不同品种绿豆,筛选出营养及功能活性具佳的绿豆作为原料,在优化工艺的基础上制备萌发绿豆酸奶,以探究萌发绿豆芽粉的添加对酸奶加工品质及营养成分的影响。

1 材料与方法

1.1 材料与试剂

绿豆(明绿豆、龙博9号绿豆、毛绿豆、小鹦哥):吉林省白城市;纯牛乳、白砂糖:市售;发酵菌种(保加利亚乳杆菌∶嗜热链球菌=1∶1,活菌数1010~1012 cfu/g):市售;羧甲基纤维素钠(CMC)稳定剂、氢氧化钠、氯化钠:天津市光复科技发展有限公司;酚酞指示剂:北京新开顿科技有限公司;乳酸细菌培养基(MRS)培养基、MC培养基:奥博星有限公司;琼脂:BIO FROXX GMBH。

1.2 仪器与设备

HH-1数显恒温水浴锅:金坛市荣华仪器制造有限公司;TD5A台式离心机:长沙英泰仪器有限公司;RH-600A型高速多功能粉碎机:新乡市丰润轻工机械有限公司;DGG-9140B型电热恒温鼓风干燥箱:上海森信试验仪器有限公司;SKP01电热恒温培养箱:湖北黄石市医疗器械厂;SCIENTZ-04均质器:宁波新芝生物科技股份有限公司。

1.3 试验方法

1.3.1 绿豆前处理与萌发

对四个品种绿豆进行挑拣、清洗、浸泡处理后,置于发芽机内进行发芽,控制温度、水分等指标,恒温萌发48 h,生芽至4~5 nm。

1.3.2 凝固型萌发绿豆酸奶的制备

取萌发好的绿豆进行干燥、超微粉碎处理,将得到的萌发绿豆芽粉与 90 ℃热水按一定比例混合,使其充分糊化。将糊化液与白砂糖、稳定剂按相应比例加入牛奶中,均质(65 ℃,250 MPa)20 min后,进行巴氏杀菌。杀菌后冷却到42 ℃,进行接种,密封保存,发酵4~5 h,后熟6 h。

1.3.3 纤维含量的测定

1.3.3.1 总膳食纤维含量的测定 参考王大为等[16]对绿豆皮膳食纤维的测定方法进行测定。将萌发绿豆芽粉样品放置在膳食纤维测定仪的酶培养消化装置上经酶解处理,用预热至 60 ℃的 95%的乙醇沉淀24 h,在高效洗涤过滤系统中得到过滤残渣,干燥称重,再去除膳食纤维残渣中的蛋白质、灰分和试剂空白即为样品中的总膳食纤维。

1.3.3.2 不可溶性膳食纤维含量的测定 按总膳食纤维测定方法做相同的酶解处理,加入 0.5 g酸洗硅藻土,后将得到的残渣进行抽滤;加入70 ℃热水10 mL洗涤残渣2次,再抽滤。从高效洗涤过滤系统上取下玻璃坩埚,将带残渣的玻璃坩埚干燥、称重,除去玻璃坩埚和硅藻土的质量即为残渣的重量。残渣的重量再减去其中蛋白质和灰分的重量即为不可溶膳食纤维的重量。总膳食纤维与不可溶性膳食纤维含量差即为可溶性膳食纤维含量。

1.3.4 黄酮含量的测定

1.3.4.1 牡荆素和异牡荆素的提取方法 准确称取待测样品(2±0.01) g于50 mL离心管中,料液比按1∶20加入40 mL 75%的乙醇水溶液作为提取剂,涡旋,超声 60 min,离心(4 000 r/min;10 min)取上清液于鸡心瓶中,旋蒸(60 ℃;50 r/min)至近干,准确加入4 mL乙腈定容,涡旋,将鸡心瓶中的乙腈相过0.45 μm有机微孔滤膜装进样瓶。作为待测样品溶液。

1.3.4.2 标准品溶液的制备 准确称量牡荆素和异牡荆素的标准品2 mg,以色谱纯甲醇做溶剂,将标准品稀释成0.1 mg/mL的标准品溶液,4 ℃冷藏。

1.3.4.3 色谱条件 参考常强等的测定方法确定如下色谱条件[17]。色谱柱:EC-C18(4.6×150 mm),检测器:DAD(二极管阵列检测器),进样量:2 μL,流量:1 mL/min,柱温:35 ℃,检测波长:336 nm,流动相A为乙腈,B为0.2%乙酸水,梯度洗脱,0~30 min内A的比例由5%变为35%,B的比例由95%变为65%。

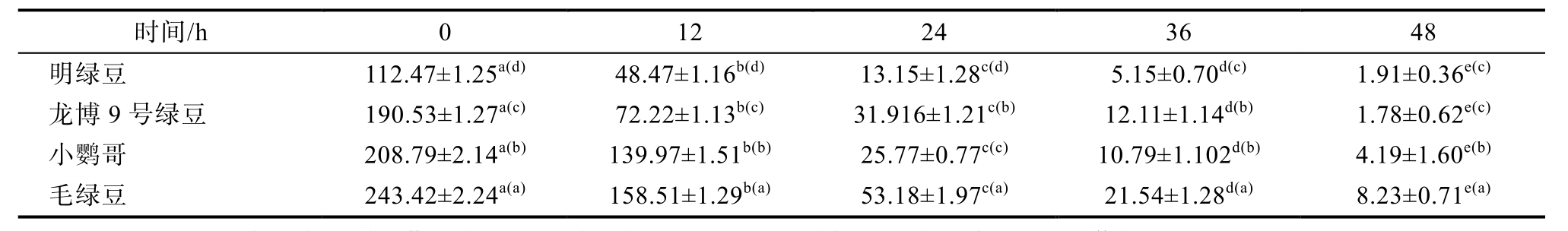

1.3.5 持水力测定

测定离心管质量m;取质量为m1的5 mL样品于离心管中,测定质量,放入高速离心机中,以3 000 r/min离心30 min后,静置5 min,倒出上清液,剩余物和离心管的总质量m2,酸奶持水率计算公式:

1.3.6 酸度测定

根据GB 5009.239—2016《食品酸度的测定》[18]进行。取萌发绿豆酸奶的待测样品10 mL、蒸馏水20 mL,放入100 mL锥形瓶中,滴入1%酚酞指示剂1~2滴,震荡均匀。用0.1 mol/L 的NaOH标准溶液进行滴定,测定消耗的NaOH标准溶液的体积,乘以10即为发酵乳酸度;将每组样品进行3次测量,取平均值作为最终滴定酸度,以吉尔涅尔度(°T)表示。

1.3.7 乳酸菌计数(平板计数法)

根据GB 4389.35—2016《食品乳酸菌检验》[19]进行测定。取均匀待测样品25 g加入到225 mL生理盐水中,均质,得到稀释比例为1:10的稀释液后,注入到含有生理盐水的试管中,依次10倍梯度稀释,得到得到 1×10–6、1×10–7、1×10–8 三种梯度样品稀释液。取 1 mL稀释样液分别注入含有15 mL MRS琼脂培养基和15 mLMC琼脂培养基的平皿中,轻微摇晃均匀,每种稀释梯度做三个平行样,放入温度为(36 ± 1) ℃的恒温培养箱中培养3 d后,计乳酸菌总数,取平均值,记为最终数值。

1.3.8 感官评定(双盲法)

按照国标 GB19302—2010《食品安全国家标准发酵乳》对萌发绿豆酸奶的凝乳状态、乳清析出情况、色泽、香味以及口感的综合感官评定进行打分,参考李海涛[20]等的评定方法,确定感官评价标准如下,取多人评分的平均值作为萌发绿豆酸奶的感官评分。

1.3.9 其他指标测定

各理化指标检测:脂肪含量、蛋白质含量、微生物指标(乳酸菌数、大肠菌群、金黄色葡萄球菌、沙门氏菌、酵母、霉菌)均按照国标 GB 19302—2010《发酵乳》[21]进行检测。

1.3.10 单因素、正交试验

在主要影响萌发绿豆酸奶品质的四个单因素试验的基础上,以感官评分作为最终判定标准,以萌发绿豆芽粉、蔗糖、CMC稳定剂、菌种添加量为主要研究因素,采用L9(34)正交试验(表2),确定萌发绿豆酸奶的最佳配方。

表1 凝固型绿豆酸奶感官评价标准

Table 1 Standards of sensory evaluation of the set yoghurt with mung bean

images/BZ_167_311_614_450_662.pngimages/BZ_167_711_614_850_662.pngimages/BZ_167_1059_614_1173_662.pngimages/BZ_167_269_702_408_750.pngimages/BZ_167_544_678_1017_726.pngimages/BZ_167_544_726_788_775.pngimages/BZ_167_1099_706_1134_745.pngimages/BZ_167_269_789_477_837.pngimages/BZ_167_544_789_788_837.pngimages/BZ_167_1099_792_1134_832.pngimages/BZ_167_269_848_338_896.pngimages/BZ_167_544_848_718_896.pngimages/BZ_167_1099_852_1134_891.pngimages/BZ_167_269_907_338_955.pngimages/BZ_167_544_907_892_955.pngimages/BZ_167_1099_911_1134_950.pngimages/BZ_167_269_966_338_1014.pngimages/BZ_167_544_966_683_1014.pngimages/BZ_167_1099_970_1134_1009.png

表2 萌发绿豆酸奶化正交试验因素水平表

Table 2 Table of factors in orthogonal experiment of germination of mung bean yoghurt

images/BZ_167_724_1730_794_1778.pngimages/BZ_167_244_1786_313_1834.pngimages/BZ_167_331_1794_551_1842.pngimages/BZ_167_370_1842_513_1890.pngimages/BZ_167_577_1794_721_1842.pngimages/BZ_167_595_1842_703_1890.pngimages/BZ_167_758_1794_972_1842.pngimages/BZ_167_776_1842_954_1890.pngimages/BZ_167_1021_1794_1168_1842.pngimages/BZ_167_1019_1842_1170_1890.pngimages/BZ_167_270_1910_290_1950.pngimages/BZ_167_419_1910_463_1950.pngimages/BZ_167_640_1910_660_1950.pngimages/BZ_167_856_1910_876_1950.pngimages/BZ_167_1072_1910_1089_1950.pngimages/BZ_167_270_1970_289_2009.pngimages/BZ_167_419_1970_463_2009.pngimages/BZ_167_640_1970_659_2009.pngimages/BZ_167_856_1970_875_2009.pngimages/BZ_167_1072_1970_1116_2009.pngimages/BZ_167_270_2029_289_2068.pngimages/BZ_167_419_2029_463_2068.pngimages/BZ_167_640_2029_659_2068.pngimages/BZ_167_856_2029_875_2068.pngimages/BZ_167_1072_2029_1089_2068.png

1.3.11 萌发绿豆酸奶抗氧化性测定

1.3.11.1 DPPH自由基清除率测定 将萌发绿豆酸奶于离心机(4 000 min/r)中离心10 min,取上清液,备用。参考王丹的方法[22]测定萌发绿豆酸奶对DPPH自由基的抗氧化性,以原味酸奶、绿豆酸奶作为对照。

1.3.11.2 羟自由基清除率测定 将萌发绿豆酸奶于离心机(4 000 min/r)中离心10 min,取上清液,备用。参考孙鲜明的方法[23]测定萌发绿豆酸奶对羟自由基的抗氧化性,以原味酸奶、绿豆酸奶作为对照。

1.4 数据处理

数据分析应用Excel及IBM SPSS Statistics 23数据统计软件。

2 结果与分析

2.1 绿豆品种的选择

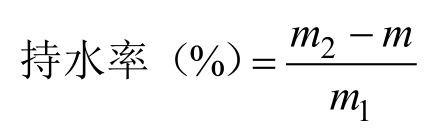

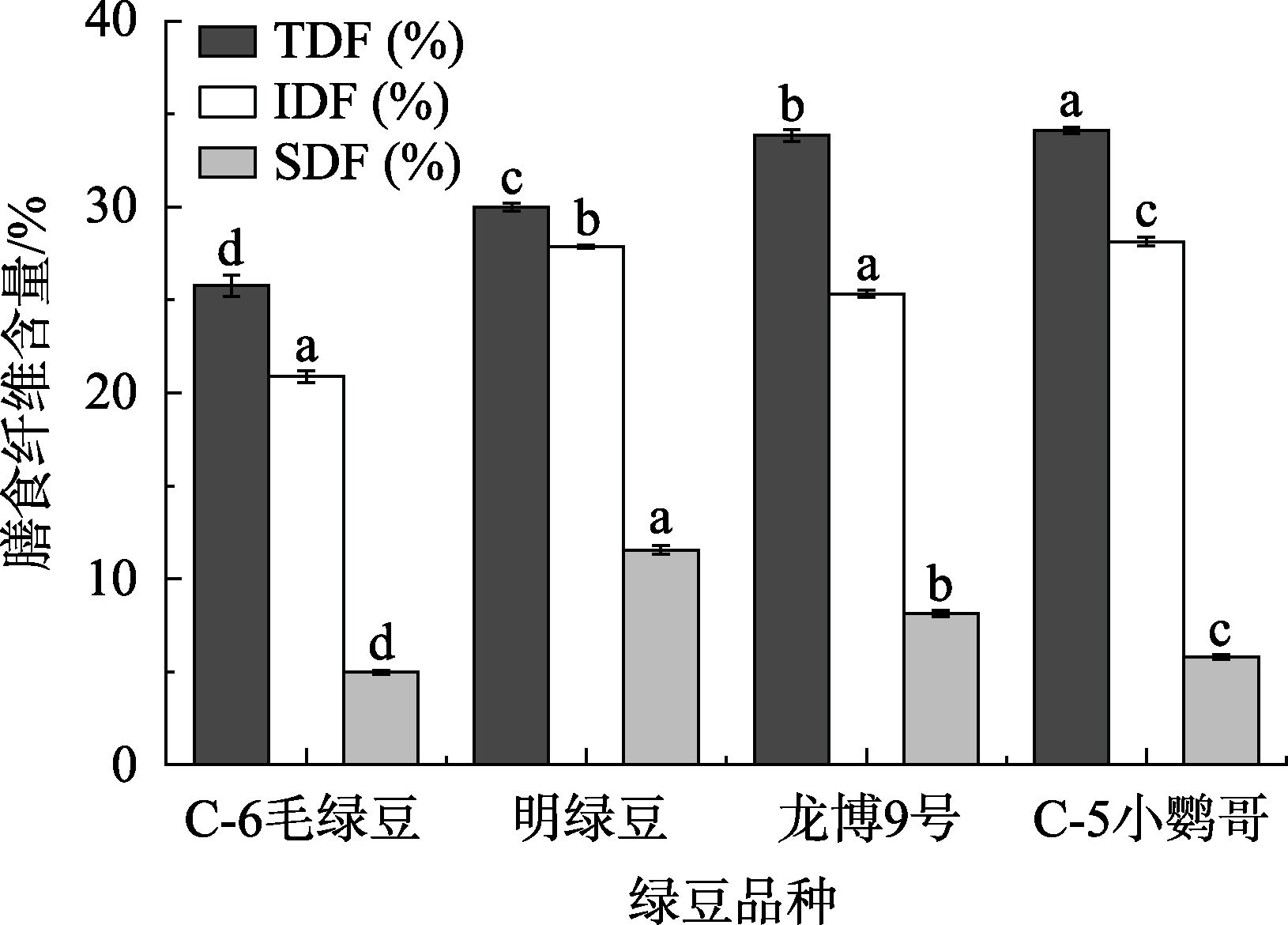

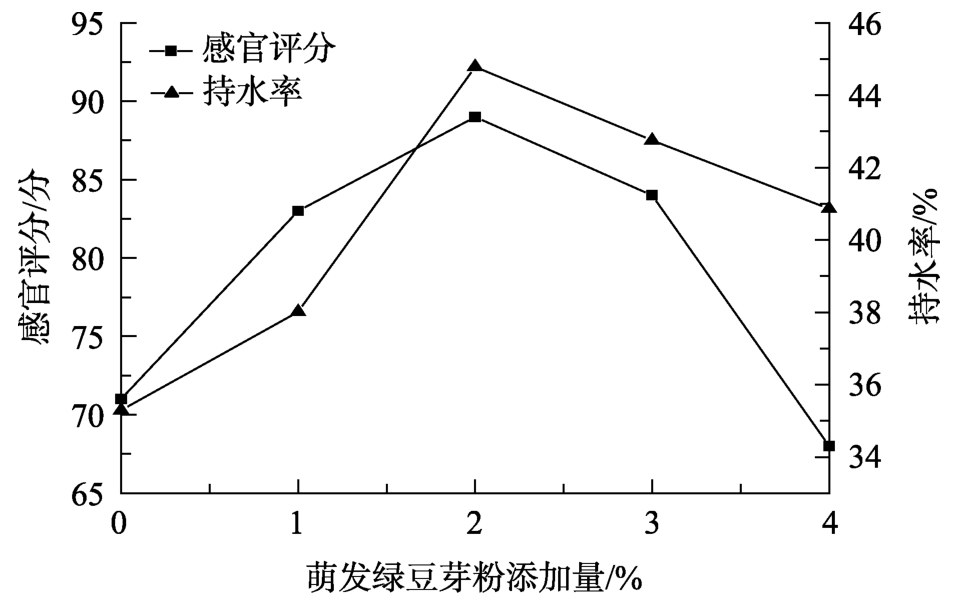

测得四个品种绿豆萌发过程中总纤维素、总黄酮含量变化如图1、表3~4所示。

由图1可知,萌发48 h后,各个品种绿豆中总膳食纤维含量呈显著性差异;毛绿豆和龙博 9号绿豆中不可溶性膳食纤维含量无显著性差异,与另两个品种差异显著;四个品种中可溶性膳食纤维含量差异性显著。可溶性膳食纤维以明绿豆和龙博9号绿豆中含量最高。

图1 萌发48 h后各品种绿豆的总膳食纤维含量

Fig.1 Changes of dietary fiber content in mung bean varieties during germination time of 48 h

本试验以四个品种绿豆萌发后可溶性膳食纤维、牡荆素和异牡荆素含量为主要指标,优选出制备萌发绿豆酸奶的最佳品种绿豆。综合图 1、表3~4来看,绿豆萌发48 h后,龙博9号品种绿豆最优,因此后续试验均选取该品种绿豆。

表3 萌发48 h各品种绿豆中牡荆素含量比较

Table 3 Comparison of the vitexin content of mung bean sprouts in germination 48 h μg/g

注:括号里面字母表示同一萌发阶段,不同品种之间的差异性(字母不同,则差异性显著)(P<0.05)。

Note:The letters in the parentheses indicate the differences between different varieties at the same germination stage (the letters are different,the difference is significant) (P<0.05).

images/BZ_167_238_2864_635_2912.png images/BZ_167_638_2869_956_2907.pngimages/BZ_167_959_2869_1278_2907.pngimages/BZ_167_1281_2869_1600_2907.pngimages/BZ_167_1603_2869_1921_2907.pngimages/BZ_167_1924_2869_2243_2907.pngimages/BZ_167_238_2914_635_2962.pngimages/BZ_167_638_2919_956_2957.pngimages/BZ_167_959_2919_1278_2957.pngimages/BZ_167_1281_2919_1600_2957.pngimages/BZ_167_1603_2919_1921_2957.pngimages/BZ_167_1924_2919_2243_2957.pngimages/BZ_167_238_2962_635_3011.pngimages/BZ_167_638_2967_956_3006.pngimages/BZ_167_959_2967_1278_3006.pngimages/BZ_167_1281_2967_1600_3006.pngimages/BZ_167_1603_2967_1921_3006.pngimages/BZ_167_1924_2967_2243_3006.pngimages/BZ_167_238_3011_635_3059.pngimages/BZ_167_638_3016_956_3054.pngimages/BZ_167_959_3016_1278_3054.pngimages/BZ_167_1281_3016_1600_3054.pngimages/BZ_167_1603_3016_1921_3054.pngimages/BZ_167_1924_3016_2243_3054.pngimages/BZ_167_238_3059_635_3107.pngimages/BZ_167_638_3064_956_3102.pngimages/BZ_167_959_3064_1278_3102.pngimages/BZ_167_1281_3064_1600_3102.pngimages/BZ_167_1603_3064_1921_3102.pngimages/BZ_167_1924_3064_2243_3102.png

表4 萌发48 h各品种绿豆中异牡荆素含量比较

Table 4 Comparison of the isovitexin content of mung bean sprouts in germination 48 h μg/g

注:括号里面字母表示同一萌发阶段,不同品种之间的差异性(字母不同,则差异性显著)(P<0.05)。

Note:The letters in the parentheses indicate the differences between different varieties at the same germination stage (the letters are different,the difference is significant) (P<0.05).

images/BZ_168_235_373_635_426.png images/BZ_168_635_373_956_426.pngimages/BZ_168_956_373_1278_426.pngimages/BZ_168_235_428_635_481.pngimages/BZ_168_635_428_956_481.pngimages/BZ_168_956_428_1278_481.pngimages/BZ_168_235_481_635_534.pngimages/BZ_168_635_481_956_534.pngimages/BZ_168_956_481_1278_534.pngimages/BZ_168_235_534_635_587.pngimages/BZ_168_635_534_956_587.pngimages/BZ_168_956_534_1278_587.pngimages/BZ_168_235_587_635_640.pngimages/BZ_168_635_587_956_640.pngimages/BZ_168_956_587_1278_640.pngimages/BZ_168_1278_373_1600_426.pngimages/BZ_168_1600_373_1921_426.pngimages/BZ_168_1921_373_2243_426.pngimages/BZ_168_1278_428_1600_481.pngimages/BZ_168_1600_428_1921_481.pngimages/BZ_168_1921_428_2243_481.pngimages/BZ_168_1278_481_1600_534.pngimages/BZ_168_1600_481_1921_534.pngimages/BZ_168_1921_481_2243_534.pngimages/BZ_168_1278_534_1600_587.pngimages/BZ_168_1600_534_1921_587.pngimages/BZ_168_1921_534_2243_587.pngimages/BZ_168_1278_587_1600_640.pngimages/BZ_168_1600_587_1921_641.pngimages/BZ_168_1921_587_2243_640.png

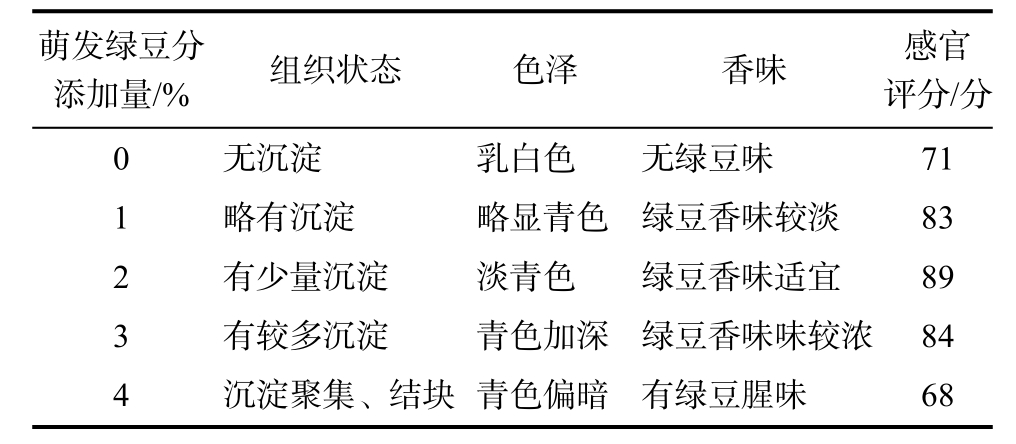

2.2 萌发绿豆芽粉添加量对酸奶品质的影响

选择 0%、1%、2%、3%、4%的萌发绿豆芽粉添加量进行研究。其中0%为未萌发绿豆芽粉添加对照组。由表5和图2可知,萌发绿豆芽粉的添加量对酸奶组织结构、风味和颜色有直接影响。相对添加未萌发绿豆芽粉,萌发绿豆芽粉的添加有利于酸奶组织结构的稳定;萌发绿豆芽粉添加量在低于1%时,几乎不具有绿豆风味,且感官评分较差;高于5%时,有明显绿豆腥味,易产生沉淀;添加量为2%时,组织结构较好,风味独特,视为最佳。

图2 萌发绿豆芽粉添加量对酸奶品质的影响

Fig.2 Effect of addition of germinated mung bean powder on quality of yogurt

表5 酸奶中萌发绿豆芽粉的添加量对成品品质的影响

Table 5 Effect of addition of germinated mung bean powder in yogurt on product quality

images/BZ_168_240_2043_406_2091.pngimages/BZ_168_1107_2043_1173_2091.pngimages/BZ_168_255_2092_392_2140.pngimages/BZ_168_472_2067_605_2115.pngimages/BZ_168_714_2067_781_2115.pngimages/BZ_168_923_2067_990_2115.pngimages/BZ_168_315_2159_335_2199.pngimages/BZ_168_425_2156_525_2204.pngimages/BZ_168_678_2156_778_2204.pngimages/BZ_168_844_2156_976_2204.pngimages/BZ_168_1123_2159_1157_2199.pngimages/BZ_168_315_2218_335_2258.pngimages/BZ_168_425_2215_558_2263.pngimages/BZ_168_678_2215_811_2263.pngimages/BZ_168_844_2215_1043_2263.pngimages/BZ_168_1123_2218_1157_2258.pngimages/BZ_168_315_2278_334_2317.pngimages/BZ_168_425_2274_591_2322.pngimages/BZ_168_678_2274_778_2322.pngimages/BZ_168_844_2274_1043_2322.pngimages/BZ_168_1123_2278_1157_2317.pngimages/BZ_168_315_2337_334_2376.pngimages/BZ_168_425_2333_591_2381.pngimages/BZ_168_678_2333_811_2381.pngimages/BZ_168_844_2333_1076_2381.pngimages/BZ_168_1123_2337_1157_2376.pngimages/BZ_168_315_2396_334_2435.pngimages/BZ_168_425_2392_658_2440.pngimages/BZ_168_678_2392_811_2440.pngimages/BZ_168_844_2392_1010_2440.pngimages/BZ_168_1123_2396_1157_2435.pngimages/BZ_168_1085_2092_1194_2140.png

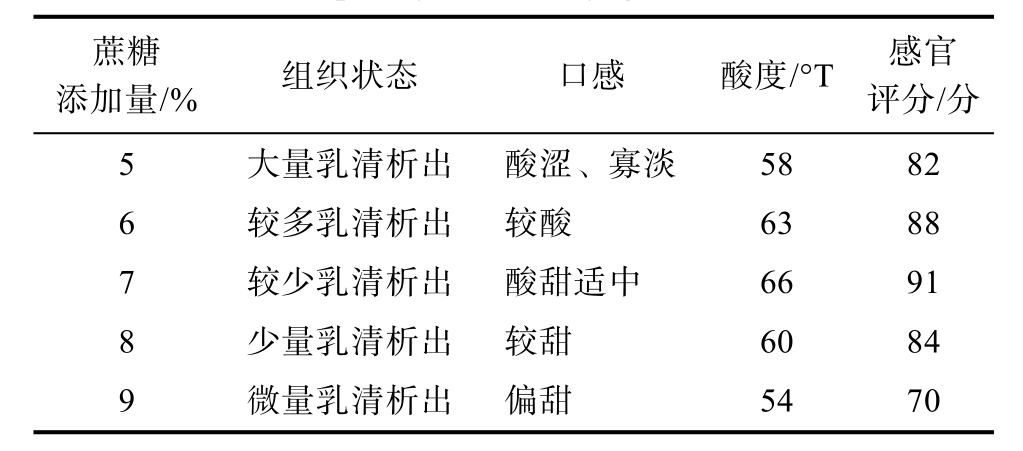

2.3 蔗糖添加量对酸奶品质的影响

在发酵温度为 42 ℃,萌发绿豆芽粉添加量为2%的条件下,探究5%、6%、7%、8%、9%的蔗糖添加量对酸奶品质的影响。酸奶中乳酸菌的发酵依赖的主要碳源为蔗糖,所以其添加量直接决定乳酸菌的产酸量,间接影响发酵速度以及产品的酸甜度。由表6和图3看出,蔗糖添加量对酸奶的组织结构和酸度的影响显著。添加量少于6%时,酸奶凝乳状态差,乳清析出多,口感酸涩;添加量大于8%时,会增大乳酸菌渗透压,降低其活性,降低发酵速度,影响酸奶的发酵状态,且口感甜腻。当添加量为7%时,酸奶组织结构最佳,口感最为适宜。

图3 CMC稳定剂添加量对酸奶品质的影响

Fig.3 Effect of content of CMC stabilizer on quality of yogurt

在发酵温度为 42 ℃,萌发绿豆芽粉添加量为2%的条件下,探究5%、6%、7%、8%、9%的蔗糖添加量对酸奶品质的影响。酸奶中乳酸菌的发酵依赖的主要碳源为蔗糖,所以其添加量直接决定乳酸菌的产酸量,间接影响发酵速度以及产品的酸甜度。由表6看出,蔗糖添加量对酸奶的组织结构和酸度的影响显著。添加量少于6%时,酸奶凝乳状态差,乳清析出多,口感酸涩;添加量大于8%时,会增大乳酸菌渗透压,降低其活性,降低发酵速度,影响酸奶的发酵状态,且口感甜腻。当添加量为7%时,酸奶组织结构最佳,口感最为适宜。

表6 酸奶中蔗糖的添加量对成品品质的影响

Table 6 Effect of saccharose amount on the quality of the set yoghurt

images/BZ_168_1341_2081_1411_2129.pngimages/BZ_168_2138_2081_2208_2129.pngimages/BZ_168_1304_2129_1447_2177.pngimages/BZ_168_1531_2105_1669_2153.pngimages/BZ_168_1806_2105_1876_2153.pngimages/BZ_168_1969_2105_2084_2153.png images/BZ_168_2116_2129_2230_2177.pngimages/BZ_168_1367_2197_1386_2236.pngimages/BZ_168_1496_2193_1704_2241.pngimages/BZ_168_1753_2193_1927_2241.pngimages/BZ_168_2009_2197_2044_2236.pngimages/BZ_168_2156_2197_2191_2236.pngimages/BZ_168_1367_2256_1386_2295.pngimages/BZ_168_1496_2252_1704_2300.pngimages/BZ_168_1753_2252_1823_2300.pngimages/BZ_168_2009_2256_2044_2295.pngimages/BZ_168_2156_2256_2191_2295.pngimages/BZ_168_1367_2315_1386_2354.pngimages/BZ_168_1496_2311_1704_2359.pngimages/BZ_168_1753_2311_1893_2359.pngimages/BZ_168_2009_2315_2044_2354.pngimages/BZ_168_2156_2315_2191_2354.pngimages/BZ_168_1367_2374_1387_2414.pngimages/BZ_168_1496_2371_1704_2419.pngimages/BZ_168_1753_2371_1823_2419.pngimages/BZ_168_2009_2374_2044_2414.pngimages/BZ_168_2156_2374_2191_2414.pngimages/BZ_168_1367_2434_1386_2473.pngimages/BZ_168_1496_2430_1704_2478.pngimages/BZ_168_1753_2430_1823_2478.pngimages/BZ_168_2009_2434_2044_2473.pngimages/BZ_168_2156_2434_2191_2473.png

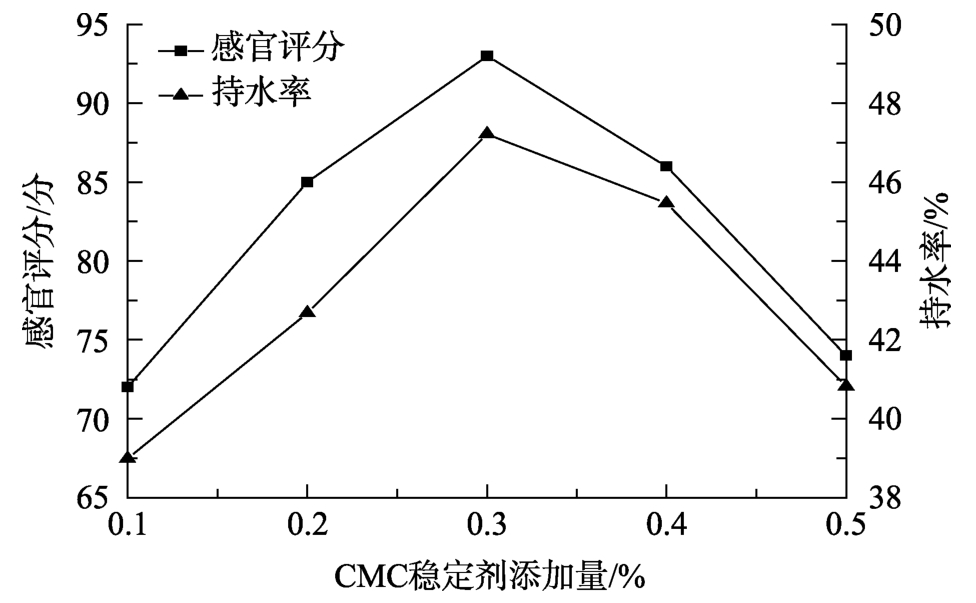

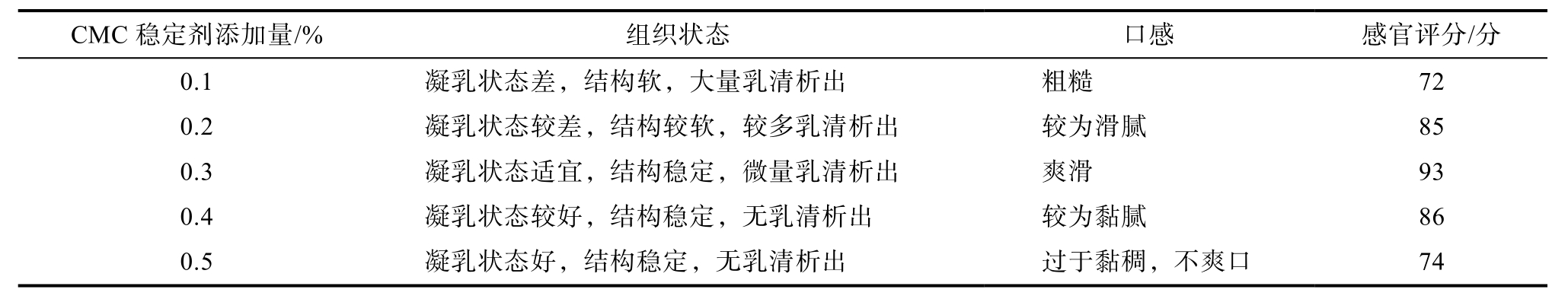

2.4 CMC稳定剂添加量对酸奶品质的影响

在发酵温度为 42 ℃,萌发绿豆芽粉添加量为2%,蔗糖添加量为7%的条件下,探究0.1%~0.5%的CMC稳定剂的添加量对酸奶品质的影响。绿豆中蛋白质和淀粉含量达80%左右,易导致酸奶凝乳状态差,产生分层沉淀现象。CMC稳定剂具有增加酸奶品质稳定性以及口感滑腻性的作用。由表7和图3可以看出,CMC稳定剂的添加量对酸奶品质有明显影响。添加量低于2%时,容易导致乳清析出,凝乳状态差,口感稀松;添加量多于0.4%时,口感过于黏腻,粘口不清爽。CMC稳定剂添加量为0.3%时,酸奶凝乳状态适宜,结构稳定,爽口,视为最佳。

表7 酸奶中CMC稳定剂的添加量对成品品质的影响

Table 7 Effect of stabilizer amount on the quality of the set yoghurt

images/BZ_169_304_1254_636_1302.pngimages/BZ_169_1033_1254_1172_1302.pngimages/BZ_169_448_1319_492_1358.pngimages/BZ_169_1685_1254_1755_1302.pngimages/BZ_169_2000_1254_2183_1302.pngimages/BZ_169_769_1315_1325_1363.pngimages/BZ_169_448_1378_492_1417.pngimages/BZ_169_1579_1315_1648_1363.pngimages/BZ_169_2074_1319_2109_1358.pngimages/BZ_169_769_1374_1394_1422.pngimages/BZ_169_448_1437_492_1476.pngimages/BZ_169_1579_1374_1718_1422.pngimages/BZ_169_2074_1378_2109_1417.pngimages/BZ_169_769_1434_1394_1482.pngimages/BZ_169_448_1496_492_1536.pngimages/BZ_169_1579_1434_1648_1482.pngimages/BZ_169_2074_1437_2109_1476.pngimages/BZ_169_769_1493_1360_1541.pngimages/BZ_169_448_1555_492_1595.pngimages/BZ_169_1579_1493_1718_1541.pngimages/BZ_169_2074_1496_2109_1536.pngimages/BZ_169_769_1552_1325_1600.pngimages/BZ_169_1579_1552_1857_1600.pngimages/BZ_169_2074_1555_2109_1595.png

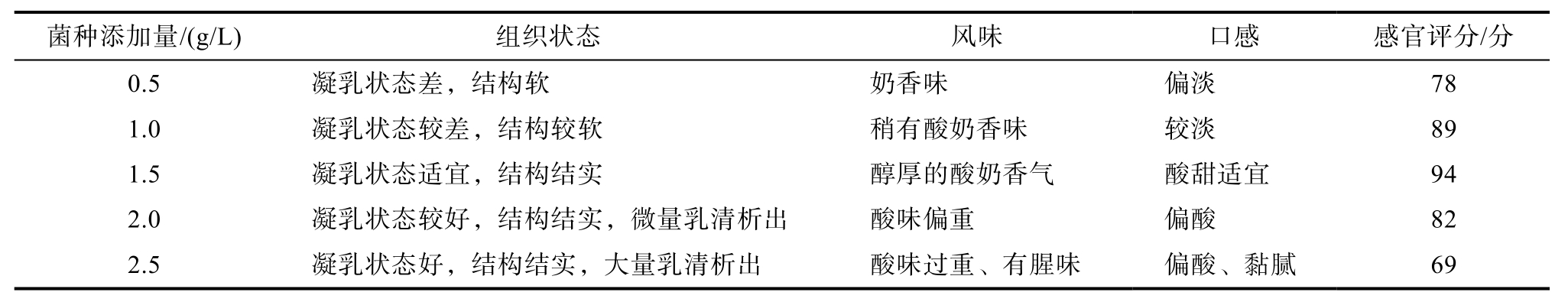

2.5 菌种添加量对酸奶品质的影响

乳酸菌添加量主要影响酸奶中乳酸菌活菌数的数量,间接影响其产酸量。在发酵温度为42 ℃,萌发绿豆芽粉添加量为2%,蔗糖添加量为7%,CMC稳定剂添加量为 0.3%的条件下,探究 0.5~2.5 g/L的菌种添加量对酸奶品质的影响。由图4和表8可以看出,菌种添加量对酸奶结构口感有显著影响。添加量过少,产生的乳酸量不足,发酵速度缓慢,酸奶凝乳状态较差;添加量过多,产酸量过多,发酵速度过快,导致凝乳结构松散,易使酸奶产生沉淀。菌种添加量为1.5 g/L,酸奶凝乳状态最佳,风味、口感最为适宜。

图4 菌种添加量对酸奶品质的影响

Fig.4 Effect of bacteria adding amount on quality of yoghurt

表8 酸奶中菌种的添加量对成品品质的影响

Table 8 Effect of bacteria adding amount on quality of solidified yoghurt

images/BZ_169_277_2270_533_2318.pngimages/BZ_169_865_2270_1004_2318.pngimages/BZ_169_383_2335_427_2374.pngimages/BZ_169_624_2331_937_2379.pngimages/BZ_169_383_2394_427_2434.pngimages/BZ_169_624_2391_1006_2439.pngimages/BZ_169_383_2453_427_2493.pngimages/BZ_169_624_2450_1006_2498.pngimages/BZ_169_383_2513_427_2552.pngimages/BZ_169_624_2509_1250_2557.pngimages/BZ_169_383_2572_427_2611.pngimages/BZ_169_624_2568_1215_2616.pngimages/BZ_169_1460_2270_1530_2318.pngimages/BZ_169_1796_2270_1865_2318.pngimages/BZ_169_2013_2270_2197_2318.pngimages/BZ_169_1354_2331_1458_2379.pngimages/BZ_169_1739_2331_1808_2379.pngimages/BZ_169_2088_2335_2123_2374.pngimages/BZ_169_1354_2391_1563_2439.pngimages/BZ_169_1739_2391_1808_2439.pngimages/BZ_169_2088_2394_2123_2434.pngimages/BZ_169_1354_2450_1597_2498.pngimages/BZ_169_1739_2450_1878_2498.pngimages/BZ_169_2088_2453_2123_2493.pngimages/BZ_169_1354_2509_1493_2557.pngimages/BZ_169_1739_2509_1808_2557.pngimages/BZ_169_2088_2513_2123_2552.pngimages/BZ_169_1354_2568_1632_2616.pngimages/BZ_169_1739_2568_1913_2616.pngimages/BZ_169_2088_2572_2123_2611.png

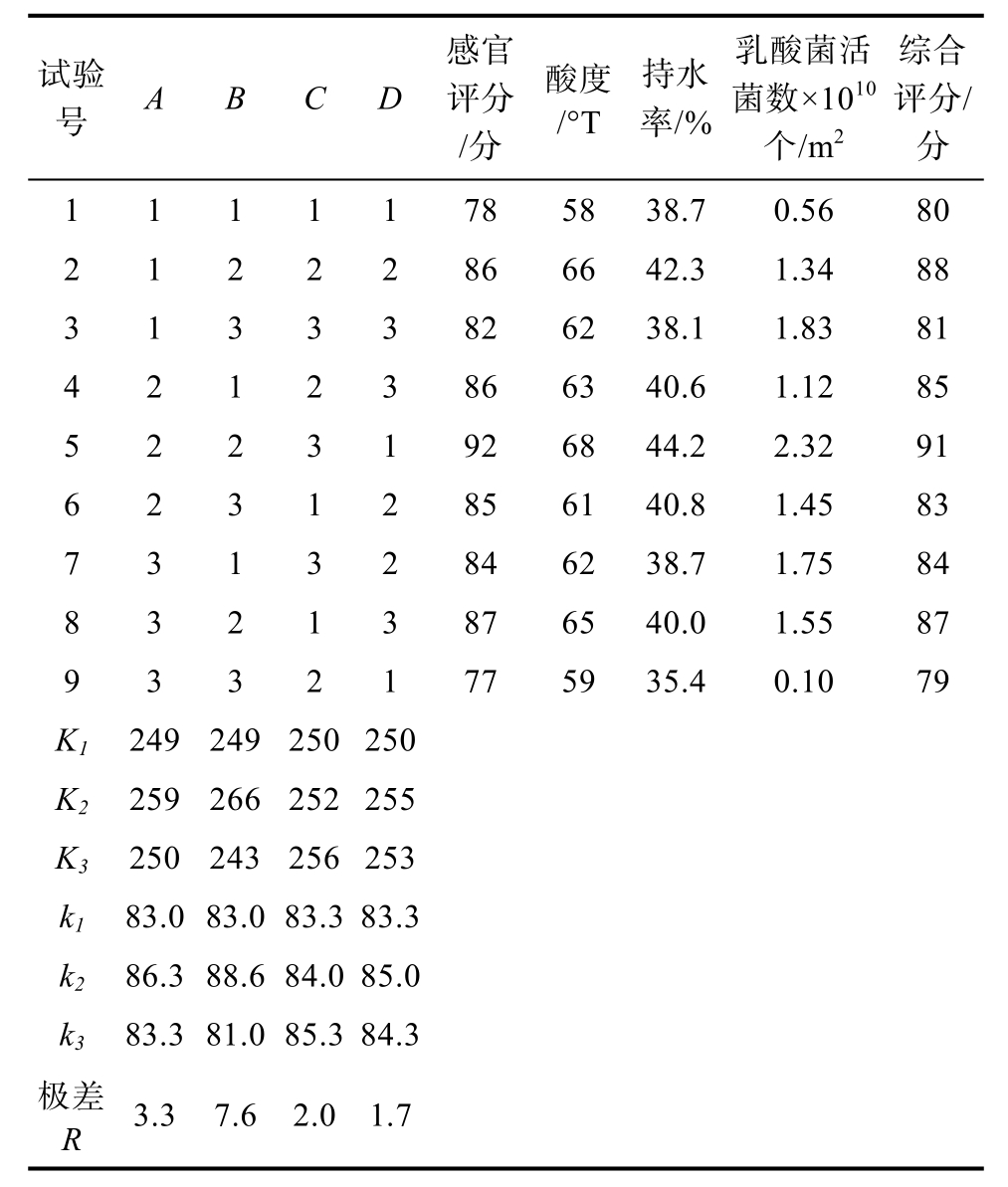

2.6 萌发绿豆酸奶的正交优化试验

本试验以萌发绿豆酸奶的感官评分、酸度、持水率、乳酸菌活菌数四个指标的加权评分作为综合评价指标,以萌发绿豆酸奶的感官评分为主要指标,乳酸菌活菌数、酸度、持水力为次要指标,权重系数比为0.5、0.3、0.1、0.1。综合评分=(感官评分/满分 100分)×50+(样品乳酸菌活菌数/酸奶的最大乳酸菌活菌数)×30+(样品酸度/酸奶的最大酸度值)×10+(样品持水率/酸奶的最大持水率)×10,分析结果见表9。

由表 9可以看出,影响萌发绿豆酸奶品质的因素顺序为B>A>C>D,即蔗糖添加量>CMC稳定剂添加量>萌发绿豆芽粉添加量>乳酸菌添加量,得出最佳组合为A2B2C3D2,即萌发绿豆芽粉添加量为2%、蔗糖添加量为7%、CMC稳定剂添加量为0.3%、菌种添加量为1.5 g/L的条件下生产出的萌发绿豆酸奶为最佳状态。

表9 萌发绿豆酸奶化正交试验结果

Table 9 Orthogonal experiment results of germination mung bean yoghurt

images/BZ_170_244_1295_314_1344.pngimages/BZ_170_261_1344_296_1392.pngimages/BZ_170_352_1324_373_1363.png images/BZ_170_433_1324_454_1363.png images/BZ_170_511_1324_534_1363.png images/BZ_170_586_1324_611_1363.pngimages/BZ_170_655_1271_724_1320.pngimages/BZ_170_655_1320_724_1368.pngimages/BZ_170_667_1368_712_1416.pngimages/BZ_170_753_1301_823_1349.pngimages/BZ_170_766_1348_811_1387.pngimages/BZ_170_851_1295_921_1344.png?images/BZ_170_945_1271_1084_1320.pngimages/BZ_170_941_1320_1088_1368.pngimages/BZ_170_973_1368_1055_1416.pngimages/BZ_170_1109_1271_1179_1320.pngimages/BZ_170_1104_1320_1184_1368.pngimages/BZ_170_1127_1368_1162_1416.pngimages/BZ_170_270_1436_289_1475.pngimages/BZ_170_353_1436_372_1475.pngimages/BZ_170_434_1436_453_1475.pngimages/BZ_170_514_1436_533_1475.pngimages/BZ_170_590_1436_609_1475.pngimages/BZ_170_672_1436_707_1475.pngimages/BZ_170_771_1436_806_1475.pngimages/BZ_170_855_1436_916_1475.pngimages/BZ_170_983_1436_1045_1475.pngimages/BZ_170_1126_1436_1161_1475.pngimages/BZ_170_270_1495_290_1535.pngimages/BZ_170_353_1495_373_1535.pngimages/BZ_170_434_1495_454_1535.pngimages/BZ_170_514_1495_534_1535.pngimages/BZ_170_590_1495_610_1535.pngimages/BZ_170_672_1495_707_1535.pngimages/BZ_170_771_1495_806_1535.pngimages/BZ_170_855_1495_916_1535.pngimages/BZ_170_983_1495_1045_1535.pngimages/BZ_170_1126_1495_1161_1535.pngimages/BZ_170_270_1554_290_1594.pngimages/BZ_170_353_1554_373_1594.pngimages/BZ_170_434_1554_454_1594.pngimages/BZ_170_514_1554_534_1594.pngimages/BZ_170_590_1554_610_1594.pngimages/BZ_170_672_1554_707_1594.pngimages/BZ_170_771_1554_806_1594.pngimages/BZ_170_855_1554_916_1594.pngimages/BZ_170_983_1554_1045_1594.pngimages/BZ_170_1126_1554_1161_1594.pngimages/BZ_170_270_1614_289_1653.pngimages/BZ_170_353_1614_372_1653.pngimages/BZ_170_434_1614_453_1653.pngimages/BZ_170_514_1614_533_1653.pngimages/BZ_170_590_1614_609_1653.pngimages/BZ_170_672_1614_707_1653.pngimages/BZ_170_771_1614_806_1653.pngimages/BZ_170_855_1614_916_1653.pngimages/BZ_170_983_1614_1045_1653.pngimages/BZ_170_1126_1614_1161_1653.pngimages/BZ_170_270_1673_289_1712.pngimages/BZ_170_353_1673_372_1712.pngimages/BZ_170_434_1673_453_1712.pngimages/BZ_170_514_1673_533_1712.pngimages/BZ_170_590_1673_609_1712.pngimages/BZ_170_672_1673_707_1712.pngimages/BZ_170_771_1673_806_1712.pngimages/BZ_170_855_1673_916_1712.pngimages/BZ_170_983_1673_1045_1712.pngimages/BZ_170_1126_1673_1161_1712.pngimages/BZ_170_270_1732_289_1771.pngimages/BZ_170_353_1732_372_1771.pngimages/BZ_170_434_1732_453_1771.pngimages/BZ_170_514_1732_533_1771.pngimages/BZ_170_590_1732_609_1771.pngimages/BZ_170_672_1732_707_1771.pngimages/BZ_170_771_1732_806_1771.pngimages/BZ_170_855_1732_916_1771.pngimages/BZ_170_983_1732_1045_1771.pngimages/BZ_170_1126_1732_1161_1771.pngimages/BZ_170_270_1791_289_1830.pngimages/BZ_170_353_1791_372_1830.pngimages/BZ_170_434_1791_453_1830.pngimages/BZ_170_514_1791_533_1830.pngimages/BZ_170_590_1791_609_1830.pngimages/BZ_170_672_1791_707_1830.pngimages/BZ_170_771_1791_806_1830.pngimages/BZ_170_855_1791_916_1830.pngimages/BZ_170_983_1791_1045_1830.pngimages/BZ_170_1126_1791_1161_1830.pngimages/BZ_170_270_1850_290_1890.pngimages/BZ_170_353_1850_373_1890.pngimages/BZ_170_434_1850_454_1890.pngimages/BZ_170_514_1850_534_1890.pngimages/BZ_170_590_1850_610_1890.pngimages/BZ_170_672_1850_707_1890.pngimages/BZ_170_771_1850_806_1890.pngimages/BZ_170_855_1850_916_1890.pngimages/BZ_170_983_1850_1045_1890.pngimages/BZ_170_1126_1850_1161_1890.pngimages/BZ_170_270_1910_289_1949.pngimages/BZ_170_353_1910_372_1949.pngimages/BZ_170_434_1910_453_1949.pngimages/BZ_170_514_1910_533_1949.pngimages/BZ_170_590_1910_609_1949.pngimages/BZ_170_672_1910_707_1949.pngimages/BZ_170_771_1910_806_1949.pngimages/BZ_170_855_1910_916_1949.pngimages/BZ_170_983_1910_1045_1949.pngimages/BZ_170_1126_1910_1161_1949.pngimages/BZ_170_261_1968_296_2008.pngimages/BZ_170_336_1968_388_2008.pngimages/BZ_170_417_1968_469_2008.pngimages/BZ_170_496_1968_549_2008.pngimages/BZ_170_572_1968_625_2008.pngimages/BZ_170_261_2028_296_2067.pngimages/BZ_170_336_2028_388_2067.pngimages/BZ_170_417_2028_469_2067.pngimages/BZ_170_496_2028_549_2067.pngimages/BZ_170_572_2028_625_2067.pngimages/BZ_170_261_2087_296_2126.pngimages/BZ_170_336_2087_388_2126.pngimages/BZ_170_417_2087_469_2126.pngimages/BZ_170_496_2087_549_2126.pngimages/BZ_170_572_2087_625_2126.pngimages/BZ_170_265_2146_292_2185.pngimages/BZ_170_331_2146_393_2185.pngimages/BZ_170_412_2146_474_2185.pngimages/BZ_170_492_2146_553_2185.pngimages/BZ_170_568_2146_630_2185.pngimages/BZ_170_265_2205_292_2245.pngimages/BZ_170_331_2205_393_2245.pngimages/BZ_170_412_2205_474_2245.pngimages/BZ_170_492_2205_553_2245.pngimages/BZ_170_568_2205_630_2245.pngimages/BZ_170_265_2265_292_2304.pngimages/BZ_170_331_2265_393_2304.pngimages/BZ_170_412_2265_474_2304.pngimages/BZ_170_492_2265_553_2304.pngimages/BZ_170_568_2265_630_2304.pngimages/BZ_170_244_2323_320_2371.pngimages/BZ_170_268_2370_289_2409.png images/BZ_170_340_2346_384_2385.pngimages/BZ_170_421_2346_465_2385.pngimages/BZ_170_501_2346_545_2385.pngimages/BZ_170_577_2346_621_2385.png

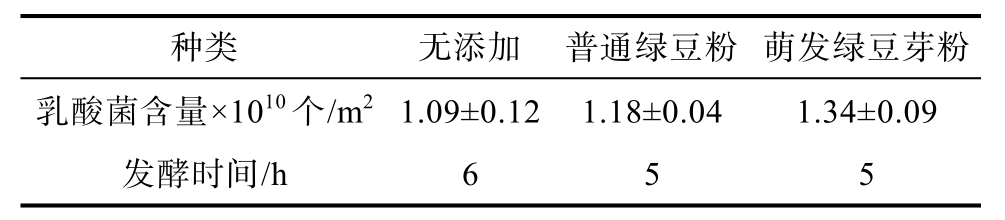

2.7 萌发绿豆芽粉酸奶的品质影响

2.7.1 对发酵的影响

根据最佳配方制作酸奶,对最终产品以及对照组中的乳酸菌进行计数,计算乳酸菌含量。由表10可知,添加萌发绿豆芽粉可以增加乳酸菌数量,一定程度上增加产酸量。萌发绿豆酸奶制作过程中发酵速度显著加快,发酵时间缩短,酸奶结构也优于另外两个对照组。

表10 萌发绿豆芽粉的添加对乳酸菌含量的影响

Table 10 Effect of germinating mung bean powder addition on lactobacillus content

images/BZ_170_1432_423_1502_471.pngimages/BZ_170_1681_423_1785_471.pngimages/BZ_170_1828_423_2001_471.pngimages/BZ_170_2025_423_2233_471.pngimages/BZ_170_1298_487_1636_535.pngimages/BZ_170_1662_491_1804_530.pngimages/BZ_170_1844_491_1986_530.pngimages/BZ_170_2058_491_2200_530.pngimages/BZ_170_1384_549_1550_597.png images/BZ_170_1724_553_1743_592.pngimages/BZ_170_1906_553_1925_592.pngimages/BZ_170_2121_553_2138_592.png

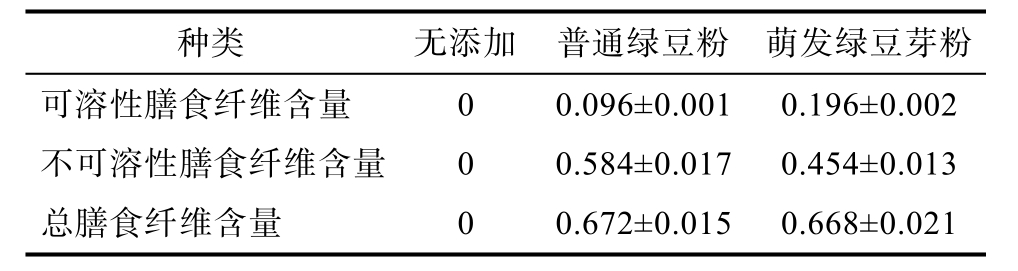

2.7.2 对膳食纤维含量的影响

由表11可知,萌发绿豆芽粉的添加,使酸奶中增添了膳食纤维,加大了酸奶对肠道菌群的调节性,同时增加降血糖、降血压等多种生理功能。

表11 萌发绿豆芽粉的添加对膳食纤维含量的影响

Table 11 Effect of germinating mung bean powder addition on dietary fiber content %

images/BZ_170_1434_808_1503_856.pngimages/BZ_170_1671_808_1775_856.pngimages/BZ_170_1814_808_1988_856.pngimages/BZ_170_2022_808_2231_856.pngimages/BZ_170_1297_870_1610_918.pngimages/BZ_170_1715_873_1735_913.pngimages/BZ_170_1813_873_1990_913.pngimages/BZ_170_2038_873_2215_913.pngimages/BZ_170_1297_929_1645_977.pngimages/BZ_170_1715_932_1735_972.pngimages/BZ_170_1813_932_1990_972.pngimages/BZ_170_2038_932_2215_972.pngimages/BZ_170_1297_988_1541_1036.pngimages/BZ_170_1715_992_1734_1031.pngimages/BZ_170_1813_992_1990_1031.pngimages/BZ_170_2038_992_2215_1031.png

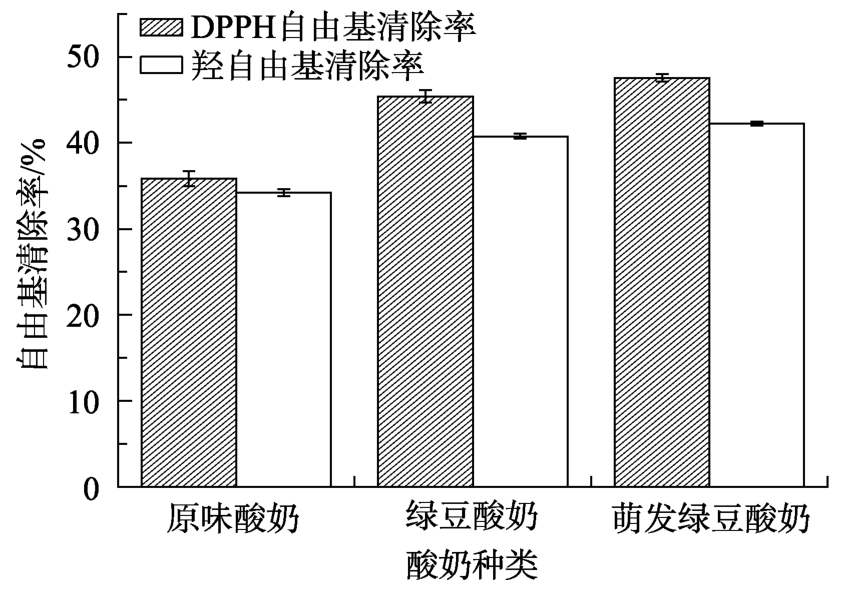

2.7.3 对抗氧化性的影响

由图 5可以看出,萌发绿豆芽粉的添加可以增强酸奶的抗氧化性,DPPH、羟自由基清除率均有显著提升;相对于普通绿豆酸奶,其自由基清除率也有显著提升。

图5 萌发绿豆芽粉的添加对自由基清除率的影响

Fig.5 Effect of adding germinated mung bean powder on free radical scavenging rate

3 结论

通过感官评定以及持水率、酸度、乳酸菌活菌数的测定,在单因素试验的基础上通过正交优化试验确定了萌发绿豆酸奶的最佳配方,即在萌发绿豆芽粉添加量为2%,蔗糖添加量为7%,CMC稳定剂添加量为0.1%,菌种添加量为1.5 g/L,灌装后于 42 ℃下培养 5 h条件下制作出的凝固型萌发绿豆酸奶,组织状态稳定,风味独特,酸甜适口。

萌发绿豆芽粉的添加对酸奶品质有明显影响,主要在组织状态、风味、乳酸菌活性、保健功能等方面体现:相较于普通绿豆粉,添加萌发绿豆芽粉可以加强酸奶组织结构,增加乳酸菌活菌数,并赋予酸奶独特的绿豆风味;同时,萌发绿豆芽粉的添加可以增强酸奶的抗氧化性,为酸奶增添了可溶性膳食纤维、牡荆素和异牡荆素等有益成分,赋予酸奶改善肠道菌群、降血压等生理保健功能。此外,通过对照组试验,可以发现萌发绿豆酸奶的综合品质与保健功能都优于普通绿豆酸奶。

[1]王立,任思,周素梅,等.绿豆发酵制品及其功能活性研究[J].食品与机械,2019,35(2):231-236.WANG L,REN S,ZHOU S M,et al.Research progress fermented food and its functional properties of mung bean[J].Food & Machinery,2019,35(2):231-236.

[2]YANG Q Q,GE Y Y,ANIL G,et al.Phenolic profiles,antioxidant activities,and antiproliferative activities of different mung bean (Vigna radiata) varieties from Sri Lanka[J].Food Bioscience,2020,37:100705.

[3]林丽婷,许秀颖,林楠,等.绿豆粉营养成分测定及加工特性研究[J].食品工业,2017,38(3):272-275.LIN L T,XU X Y,LIN N,et al.Study on determination of nutritional components and processing characteristics of powder grains[J].The Food Industry,2017,38(3):272-275.

[4]滕聪,么杨,任贵兴.绿豆功能活性及应用研究进展[J].食品安全质量检测学报,2018,9(13):3286-3291.TENG C,MO Y,REN G X.Research progress on functional activity and application of mung bean[J].Journal of Food Safety & Quality,2018,9(13):3286-3291.

[5]罗磊,王雅琪,马丽苹,等.绿豆皮可溶性膳食纤维的抗氧化作用[J].食品科学,2018,39(3):182-187.LUO L,WANG Y Q,MA L P,et al.Antioxidant effect of soluble dietary fiber from mung bean (Phaseolus radiates L.)hull[J].Food Science,2018,39(3):182-187.

[6]AKIKO H,KEISUKE H,WEI Z,et al.Mung bean (Vigna radiata(L.)) coat extract modulates macrophage functions to enhance antigen presentation:A proteomic study[J].Journal of Proteomics,2017,62:103557.

[7]MAKIUCHI T,SOBUE T,KITAMURA T,et al.The relationship between vegetable/fruit consumption and gallbladder/bile duct cancer:a population-based cohort study in Japan[J].Int.J.Cancer,2017,140:1009-1019.

[8]LI M Q,ZHANG Y J,XIA S W,et al.Finding and isolation of novel peptides with anti-proliferation ability of hepatocellular carcinoma cells from mung bean protein hydrolysates[J].Journal of Functional Foods,2019,10:35-57.

[9]LIU Y,SU C Y,AHMED S M S,et al.Effect of germination duration on structural and physicochemical properties of mung bean starch[J].International Journal of Biological Macromolecules,2020,154:706-713.

[10]赵天瑶,张亚宏,常暖迎,等.绿豆萌发过程中绿豆蛋白的功能特性及其抗氧化性[J].食品工业科技,2018,39(5):69-75.ZHAO T Y,ZHANG Y H,CHANG N Y,et al.Effects of germination on functional properties and antioxidant activity of mung bean protein[J].The Food Industry,2018,39(5):69-75.

[11]KUMAR G,XU B J.A critical review on phytochemical profile and health promoting effects of mung bean (Vigna radiata)[J].Food Science & Human Wellness,2018,7(1):11-33.

[12]李海涛,杜莹,宫俊峰,等.绿豆酸奶的研制[J].中国酿造,2019,38(1):183-187.LI H T,DU Y,GONG J F,et al.Development of mung bean yogurt[J].China Brewing,2019,38(1):183-187.

[13]申灵.含谷粒发酵绿豆酸奶的研制[J].安徽农学通报,2014,20(Z2):131-133.SHEN L.Development of mung-bean yoghurt containing grains[J].Anhui Agricultural Science Bulletin,2014,20(Z2):131-133.

[14]李海燕,乔成亚,刘振民,等.凝固型绿豆酸奶的研制[J].中国酿造,2013,32(12):141-144.LI H Y,QIAO C Y,LIU Z M,et al.Development of set yoghurt with mung bean[J].China Brewing,2013,32(12):141-144.

[15]张如意.绿豆酸奶的研制[J].食品与发酵科技,2010,46(4):92-95.ZHANG R Y.Preparayion of mung bean yogurt[J].Food and Fermentation Sciences & Technology,2010,46(4):92-95.

[16]王大为,赵鑫,董欣,等.发芽对绿豆皮膳食纤维结构及性质的影响[J].食品科学,2016,37(23):111-117.WANG D W,ZHAO X,DONG X,et al.Effect of germination on the structure and properties of dietary fiber in mung bean skin[J].Food Science,2016,37(23):111-117.

[17]常强,苏明华,陈清西,等.基于超高效液相色谱-串联质谱的橄榄果实多酚测定及其抗氧化活性分析[J].食品科学,2017,38(24):150-158.CHANG Q,SU M H,CHEN Q X,et al.Determination of polyphenols and antioxidant activity in chinese olive fruits by ultra performance liquid chromatography-tandem mass spectrometry[J].Food Science,2017,38(24):150-158.

[18]中华人民共和国国家标准.食品安全国家标准 食品酸度的测定:GB 5009.239—2016[S].中国标准出版社,2016.National standards of the people's republic of China.National standard for food safety,determination of acidity of food:GB 5009.239—2016[S].China Standard Press,2016.

[19]中华人民共和国国家标准.食品微生物学检验 乳酸菌检验:GB 4389.35—2016[S].中国标准出版社,2016.National standards of the people's republic of China.Food microbiology,examination of lactic acid bacteria:GB 4389.35—2016[S].China Standard Press,2016.

[20]李海涛,杜莹,宫俊峰,等.绿豆酸奶的研制[J].中国酿造,2019,38(1):183-187.LI H T,DU Y,GONG J F,et al.Development of mung bean yogurt[J].China Brewing,2019,38(1):183-187.

[21]中华人民共和国卫生部.食品安全国家标准 发酵乳:GB 19302—2010[S].中国标准出版社,2010.Ministry of health of the people's republic of China.Fermented milk:GB 19302—2010[S].China Standard Press,2010.

[22]王丹,翟梅枝,毛光瑞,等.核桃花粉提取物的抗氧化性研究[J].食品工业科技,2014,35(16):137-139.WANG D,ZHAI M Z,MAO G R,et al.Study on the antioxidant activity of walnut pollen extracts[J].Science and Technology of Food Industry,2014,35(16):137-139.

[23]孙鲜明,李小方,邓瑞雪,等.流苏花总黄酮超声提取工艺及抗氧化活性研究[J].食品工业科技,2015,36(16):266-272.SUN X M,LI X F,DENG R X,et al.Study on the extraction technology and antioxidant activity of total flavonoids from the flower of chionanthus retusa[J].Science and Technology of Food Industry,2015,36(16):266-272.